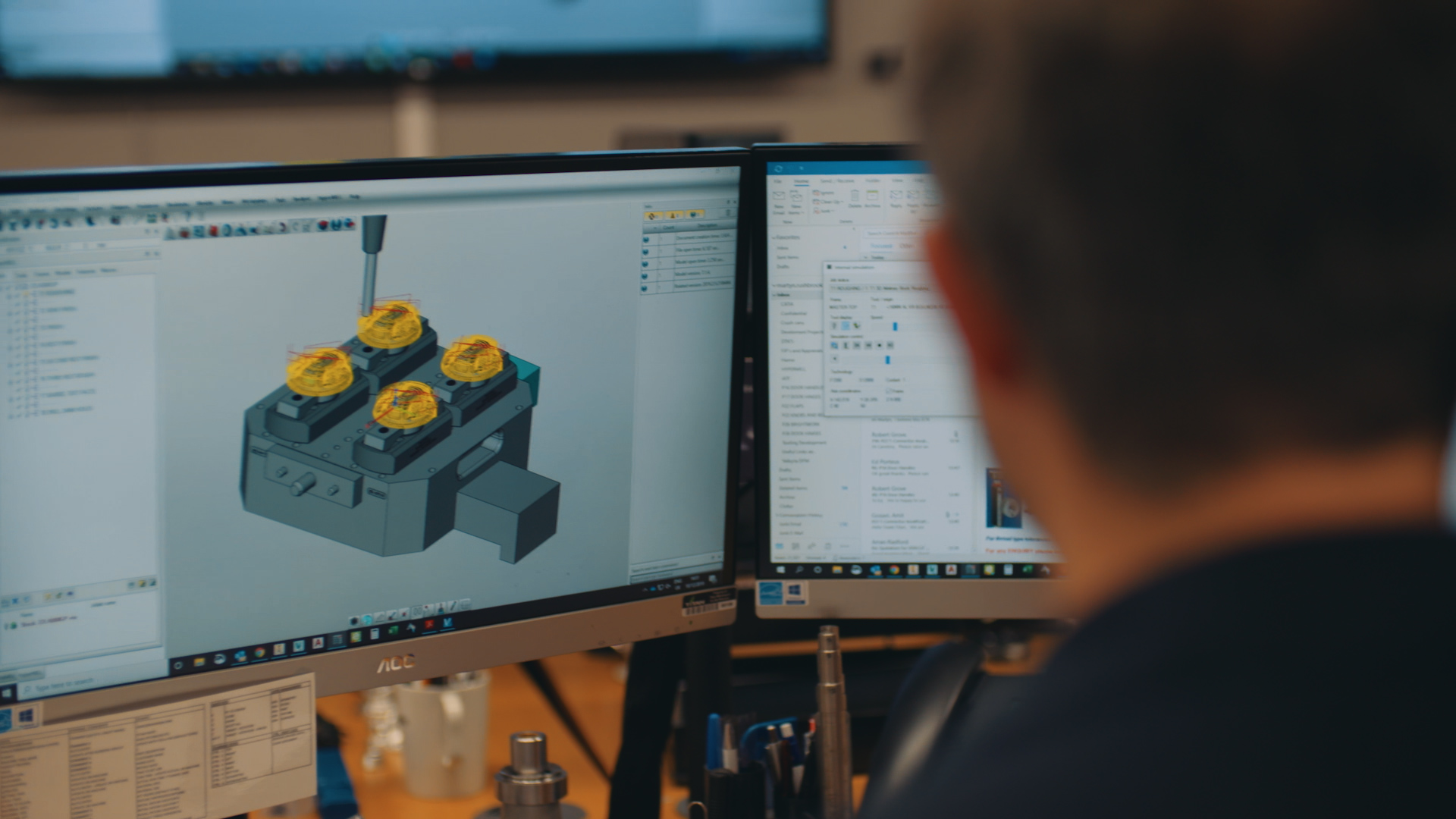

Design

Our design team uses an agile results-focused methodology to find intelligent solutions to customers’ complex engineering challenges within exacting time frames. Capabilities are expertly applied to reverse engineering of modern and historic automotive components; design optimisation for manufacturing or performance; prototype development, assembly, test and validation; and system or whole vehicle engineering.

Design

Our design team uses an agile results-focused methodology to find intelligent solutions to customers’ complex engineering challenges within exacting time frames. Capabilities are expertly applied to reverse engineering of modern and historic automotive components; design optimisation for manufacturing or performance; prototype development, assembly, test and validation; and system or whole vehicle engineering.

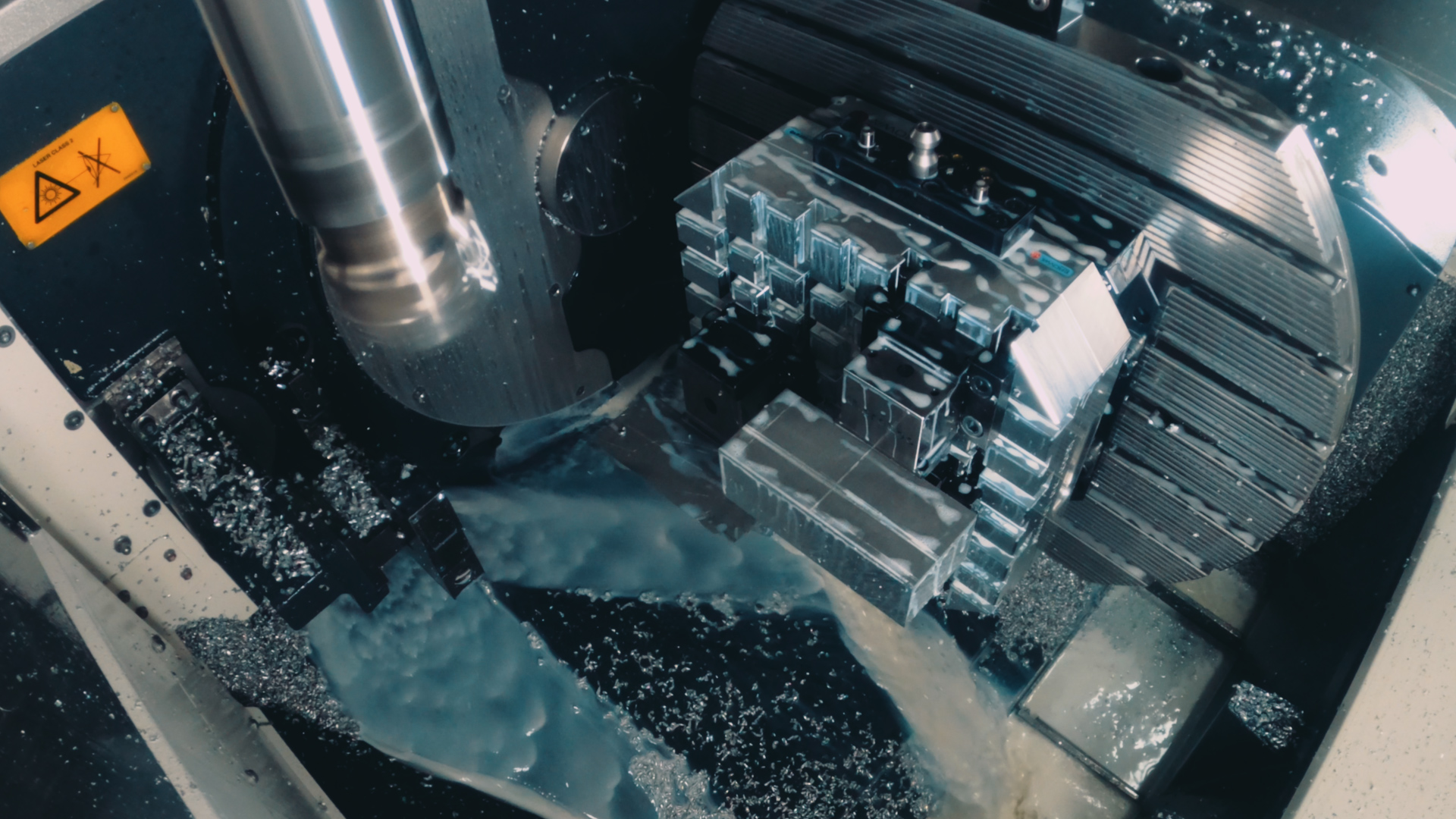

Manufacture

We’ve invested in best-in-class CNC machining, sophisticated software and training to establish Tier 1 credentials in Automotive and Motorsport.

Experienced production engineers focus on optimal manufacturing results. We have extensive 4 and 5 axis milling capability and billet and barfed turning with live tooling. Our agile approach means we are able to fast track production for critical deadlines.

Manufacture

We’ve invested in best-in-class CNC machining, sophisticated software and training to establish Tier 1 credentials in Automotive and Motorsport.

Experienced production engineers focus on optimal manufacturing results. We have extensive 4 and 5 axis milling capability and billet and barfed turning with live tooling. Our agile approach means we are able to fast track production for critical deadlines.

Assembly

Our skilled technicians are experienced in the intricate assembly of safety and performance critical components, which can be part of a complete design-to-manufacture process or stand-alone final stage assembly.

Assembly is done in a dedicated, clean and climate-controlled facility set up for large and small volume work, with separate and secure assembly for prototype and confidential builds.

Assembly

Our skilled technicians are experienced in the intricate assembly of safety and performance critical components, which can be part of a complete design-to-manufacture process or stand-alone final stage assembly.

Assembly is done in a dedicated, clean and climate-controlled facility set up for large and small volume work, with separate and secure assembly for prototype and confidential builds.

Electronics

Complete system design and development

Electronics

Complete system design and development